Kia Picanto (JA): Manual Transaxle System

Specifications

| Specifications |

|

Transaxle model

|

M5CF1-1

| |

| Engine type | Gasoline 1.0 T-GDI | |

| Manual transalxe oil | Capacity | 1.6 - 1.7 L (0.42 -0.45 U.S.gal., 1.69 - 1.80 U.S.qt., 1.41- 1.50 lmp qt.) |

| Recommended | - SAE 70W, API GL-4 · The list of transaxle oil approved by KIA: SK HK MTF 70W, SHELL SPIRAX S6 GHME 70W, GS CALTEX GS MTF HD 70W | |

| Gear ratio | 1st | 3.615 |

| 2nd | 1.955 | |

| 3rd | 1.207 | |

| 4th | 0.893 | |

| 5th | 0.703 | |

| Reverse | 3.545 | |

| Final gear ratio | 3.722/*3.833 | |

| Tightening Torques |

|

Items

|

N·m

|

kgf·m

|

lb·ft

|

| Oil drain plug | 58.9 - 78.5 | 6.0 - 8.0 | 43.4 - 57.8 |

| Oil filler plug | 58.9 - 78.5 | 6.0 - 8.0 | 43.4 - 57.8 |

| Shift lever assembly mounting bolt | 8.8 - 13.7 | 0.9 - 1.4 | 6.5 - 10.1 |

| Control cable retainer mounting nut | 11.8 - 14.7 | 1.2 - 1.5 | 8.7 - 10.8 |

| Clutch cable bracket mounting bolt | 19.6 - 26.5 | 2.0 - 2.7 | 14.5 - 19.5 |

| Back up lamp switch | 39.2 - 58.8 | 4.0 - 6.0 | 28.9 - 43.4 |

| Control shaft complete mounting bolt | 19.6 - 26.5 | 2.0 - 2.7 | 14.5 - 19.5 |

| Control cable bracket mounting bolt | 14.7 - 21.6 | 1.5 - 2.2 | 10.8 - 15.9 |

| Transaxle support bracket mounting bolt | 58.9 - 78.5 | 6.0 - 8.0 | 43.4 - 57.8 |

| Transaxle mounting bracket bolt | 88.3 - 107.9 | 9.0 - 11.0 | 65.1 - 79.6 |

| Starter mounting bolt | 49.0 - 63.7 | 5.0 - 6.5 | 36.2 - 47.0 |

| Transaxle upper mounting bolt (TM=>ENG) | 42.2 - 53.9 | 4.3 - 5.5 | 31.1 - 39.8 |

| Transaxle lower mounting bolt (ENG=>TM) | 48.1 - 53.9 | 4.9 - 5.5 | 35.4 - 39.8 |

| 42.2 - 53.9 | 4.3 - 5.5 | 31.1 - 39.8 | |

| Roll rod bracket mounting bolt | 49.0 - 63.7 | 5.0 - 6.5 | 36.2 - 47.0 |

| 107.9 - 127.5 | 11.0 - 13.0 | 79.6 - 94.0 | |

| Roll rod support bracket mounting bolt | 49.0 - 68.6 | 5.0 - 7.0 | 36.2 - 50.6 |

| Sealant |

|

Item

|

Specified sealant

|

| Control shaft complete | Anaerobic adhesives for flange |

Special service tools

| Special Service Tools |

|

Tool Name / Number

|

Illustration

|

Description

|

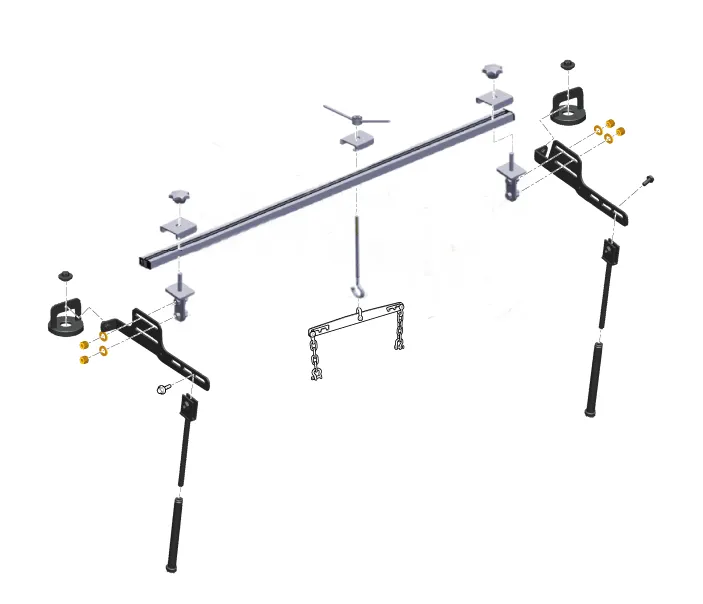

| Engine support fixture (bar) 09200-3N000 |

| Used for holding engine assembly when removing / installing transaxle Used with the adapter (09200-4X000) and supporter (09200-A3100) |

| Engine support fixture (supporter) 09200-A3100 |

| Used for holding engine assembly when removing / installing transaxle Used with the bar (09200-3N000) and adapter (09200-4X000) |

| Engine support fixture (adapter) 09200-4X000 |

| Used for holding engine assembly when removing / installing transaxle Used with the engine support bar (09200-3N000) and supporter (09200-A3100) |

| Enging hanger 09221-A3100 |

| Used for holding engine assembly when removing / installing transaxle Used with the engine support fixture |

| Oil seal installer A: 09431-23000 (Installer) B: 09231-H1100 (Handle) |

| Used for installing differential oil seal Used with the handle (09231-H1100) |

Troubleshooting

| Troubleshooting |

|

Trouble symptom

|

Suspected area

|

Remedy

|

| Abnormal noise | Oil level (Low) | Add oil after inspecting the parts (oil seal, drain plug, filler plug). |

| Oil (Wrong or contaminated) | Replace the oil. | |

| Transaxle and engine mounting state (Wrong) | Tighten the mounting bolt to specified torque. | |

| Shaft end play (Wrong) | Adjust the end play. | |

| Synchronizer ring (Worn or damaged) | Replace the synchronizer ring. | |

| Gear (Worn or damaged) | Replace the gear. | |

| Bearing (Worn or damaged) | Replace the bearing. | |

| Oil leak | Oil level (High) | Inspect the oil level. |

| Gasket (Damaged) | Replace the gasket. (drain plug, filler plug) | |

| Oil seal (Worn or damaged) | Replace the oil seal. | |

| Hard shifting or impossible to shift | Oil (Wrong) | Replace the oil. |

| Shift fork (Worn) | Replace the shift fork. | |

| Synchronizer ring (Worn or damaged) | Replace the synchronizer ring. | |

| Gear (Worn or damaged) | Replace the gear. | |

| Hub sleeve (Worn or damaged) | Replace the hub sleeve. | |

| Jumps out of gear | Shift fork (Worn) | Replace the shift fork. |

| Hub sleeve (Worn or damaged) | Replace the hub sleeve. | |

| Gear (Worn or damaged) | Replace the gear. | |

| Bearing (Worn or damaged) | Replace the bearing. |

Components and components location Components [Kappa 1.0 MPI / FFV, Kappa 1.2 MPI] 1. Clutch disc assembly 2. Clutch cover assembly 3. Clutch release bearing 4.

Other information:

Kia Picanto (JA) 2017-2026 Service & Repair Manual: Power Windows

Components and components location Component Location 1. Driver power window switch 2. Assist power window switch 3. Rear power window switch 4. Front window motor 5. Rear window motor Description and operation Safety Function of Power Window When driver door power window auto-up switch is operated, safety function is acti

Kia Picanto (JA) 2017-2026 Service & Repair Manual: Heater & A/C Control Unit(Manual)

Components and components location Components [NON ISG] Connector pin function No. Connector A Connector B 1 Low Battery 2 Common Illumination (+) 3 Ground HTD 4 Middle (Low) ISG Battery 5 Middle (High) - 6 High Detent out (-) 7 - 8 Sen

Categories

- Manuals Home

- Kia Picanto Owners Manual

- Kia Picanto Service Manual

- Indicators And Gauges

- Battery

- Body Electrical System

- New on site

- Most important about car