Kia Picanto (JA): Charging System / Battery Sensor

Description and operation

| Description |

Repair procedures

| Removal |

| 1. | Turn the ignition switch OFF. |

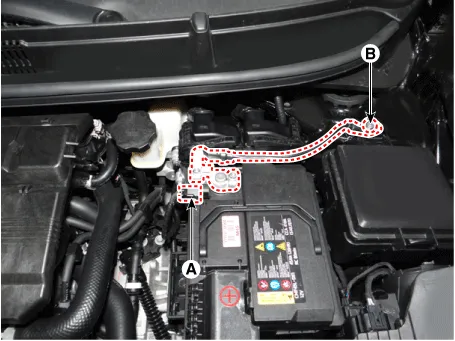

| 2. | Disconnect the battery sensor connector (A). |

| 3. | Remove the battery sensor by loosening the mounting bolts (B).

|

| Installation |

| 1. | Install in the reverse order of removal.

|

| Battery Sensor Recalibration Procedure |

| 1. | Turn the Iginition switch ON and OFF. |

| 2. | Park the vehicle for about 4 hours with the hood and all doors closed. |

Specifications Specification ▷ CMF45L-DIN Item Specification Capacity [20 hr/5 hr] (Ah) 45/36 Cold Cranking Amperage (A) 410 (SAE) / 410(EN) Reserve Capacity (min) 80 ▷ AGM50L-DIN Item Specification Capacity [20 hr/5 hr] (Ah) 50/40 Cold Cranking Amperage (A) 560 (SAE) / 560(EN) Reserve Capacity (min) 80 • Model type description • Cold Cranking Ampere (CCA): Cold Cranking Amps is a rating used in the battery industry to define a battery's ability to start an engine in cold temperatures.

Description and operation Description Ignition timing is controlled by the electronic control ignition timing system. The standard reference ignition timing data for the engine operating conditions are pre-programmed in the memory of the ECM (Engine Control Module).

Other information:

Kia Picanto (JA) 2017-2026 Service & Repair Manual: Antenna Coil

Repair procedures Removal 1.Disconnect the negative (-) battery terminal. 2.Remove the crash pad lower panel. (Refer to Body - "Crash Pad Lower Panel") 3.Remove the steering column upper and lower shroud panel. (Refer to Body - "Steering Column Shroud Panel") 4.

Kia Picanto (JA) 2017-2026 Service & Repair Manual: Heating,Ventilation, Air Conditioning

Specifications Specification Air conditioner Item Specification Compressor Type 5VSe09(Variable Dispacement Swashplate) 5VS09 Oil type & Capacity FD46XG(PAG) 100±10g Pulley type POLY V RIBBED BEIT 6PK Displacement 90cc/rev Condenser Heat rejection 9,890 -3% kcal/h

Categories

- Manuals Home

- Kia Picanto Owners Manual

- Kia Picanto Service Manual

- Body Electrical System

- Normal Condition

- Battery

- New on site

- Most important about car